HC Technical have a wide experience working closely with clients such as Hanson Aggregates, British Gypsum and Lafarge within the mining and quarrying industry. We are registered on the PICS auditing system, all our applicators hold the MPQC safety passport.

Our aim is to offer fast, effective and highly durable solutions to common problems in an aggressive fast moving environment.

We understand that any unplanned downtime is a costly event. Where possible we carry out planned works at times to suit the site production schedule, for example we will come in overnight whilst plant is not required or over weekends if necessary. For unplanned breakdowns such as a torn conveyor belt or a holed pump casing, we offer a swift response with minimum disruption to production.

Please scroll down through the case studies below to see some example applications.

Repair to Bitumen Tank Lid

A problem we often come across in asphalt plants are lids to bitumen tanks that have been eaten away by the product.

We rebuild and repair the lid in situ with no need for any hot works.

The repair shown took 1 day to repair three separate upstands on the tank lid using Belzona 1111 Supermetal and prepared steel plates, the tank did not need to be emptied for the repairs and the heaters were only switched off for a very short time whilst work was carried out.

Low friction coatings for hoppers, chutes, feeders, pumps and pipe internals

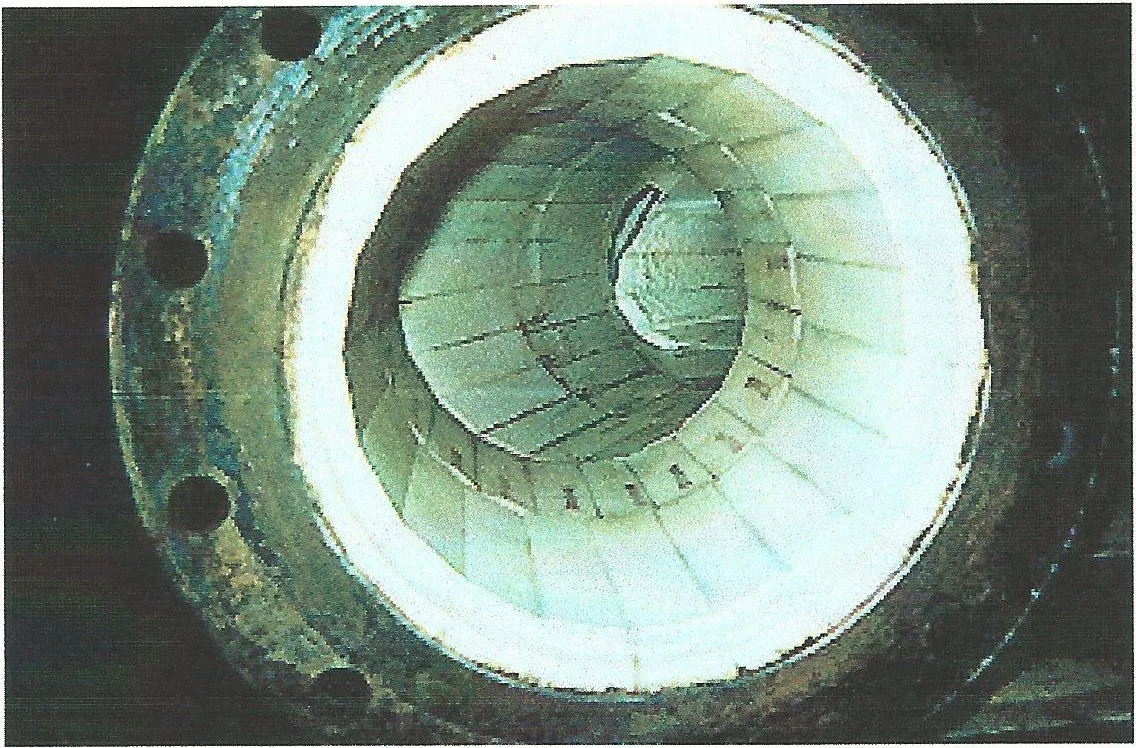

In the case study shown here the client was producing concrete and had begun to have an issue with dust building up around the sides of the hopper shown along with the impeller housing.

We gritblasted both components back to clean white metal before smoothing over any irregularities with a Belzona paste grade metal and then applied two coats of 1341 Supermetal Glide low friction coating to both components to prevent any product build up in the future.

The coating leaves an incredibly smooth but tough finish.

This is a tried and tested solution that we use commonly in many areas such as large cold feeders processing dust,chutes and hoppers and also pump internals where there is a problem with fluid causing excessive wear.

Ceramic tiling

Ceramic tiles are often used for areas experiencing high impact and abrasion, they can be applied in sections and we are able to quickly carry out repairs to damaged sections either in situ or off site at our workshop.